Unveiling the Value: Melting Copper into Bars for Profit?

07/09/2023

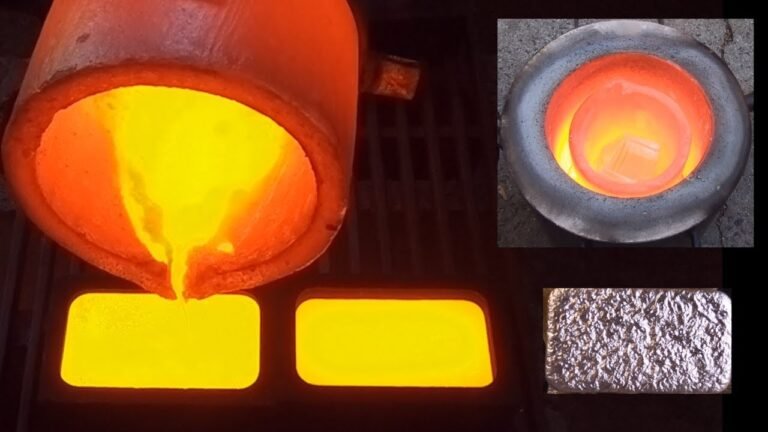

Copper, a versatile metal known for its excellent conductivity and corrosion resistance, has been valued by humans for centuries. Traditionally, copper has been used in various applications, from electrical wiring and plumbing to architectural accents and artwork. However, with the current surge in metal prices, many individuals are considering the option of melting copper into bars as a potentially lucrative venture. The process involves heating the copper to its melting point, pouring it into molds, and allowing it to cool into solid bars. This article aims to explore the pros and cons of melting copper into bars, considering factors such as cost, time, market demand, and potential profitability. By examining the various aspects of this practice, readers will gain insight into whether it is truly worth the effort and investment to transform copper into bars and potentially capitalize on the soaring metal market.

Advantages

- Higher Value: Melting copper into bars can significantly increase its value compared to selling it in its raw form. Copper bars are more sought after in industries such as construction, electronics, and manufacturing, allowing you to fetch a higher price for your copper.

- Easy Storage and Transportation: Copper bars are compact and easier to store and transport compared to bulk quantities of copper in its raw form. By melting copper into bars, you can save space and have a more organized inventory, making it more convenient to manage and transport your copper.

- Better Investment: Copper is a finite resource, and its demand continues to rise due to its various applications in industries. By melting copper into bars, you are turning it into a tangible investment that can be easily bought, sold, or traded. This can serve as a hedge against inflation and provide potential long-term returns as the demand for copper increases.

- Enhanced Purity and Quality: Melting copper into bars allows for refining and purification processes, resulting in higher purity and quality copper. This can make the copper bars more desirable for specific applications that require a certain level of purity, such as in electrical wiring or electronic components. Additionally, pure copper bars are less susceptible to corrosion, making them more durable and long-lasting.

Disadvantages

- Cost: Melting copper into bars can be an expensive process as it requires specialized equipment and energy-intensive processes. The cost of melting copper, including the purchase of equipment, raw materials, and energy consumption, may outweigh the value of the resulting copper bars.

- Time-consuming: The process of melting copper into bars can be time-consuming. It involves several steps, such as melting the copper, removing impurities, pouring the molten copper into molds, and allowing it to solidify. This lengthy process may not be practical for individuals or small-scale operations looking for quick returns.

- Skill and expertise: Melting copper into bars requires a certain level of skill and expertise. It involves precise temperature control, knowledge of metallurgy, and handling hazardous materials. Without proper training and experience, there is a risk of damaging the copper or producing bars of inferior quality.

- Market fluctuations: The value of copper bars can be influenced by market fluctuations. Copper prices are subject to supply and demand dynamics, global economic conditions, and geopolitical factors. Investing time and resources into melting copper into bars may result in an uncertain return on investment if the market value of copper drops significantly.

Does solid copper have any value?

Yes, solid copper does have value in the scrap metal market. Its value is typically higher compared to other types of scrap metal due to its high conductivity and durability. The price for solid copper can fluctuate based on several factors, such as market demand, purity, and quantity. It is advisable to research and compare prices from different buyers to ensure you get the best value for your solid copper scrap.

In the scrap metal market, solid copper holds significant value due to its conductivity and durability. Its price can vary depending on factors like market demand, purity, and quantity. To make the most profit, it's essential to research and compare prices from various buyers.

Is it possible to earn money by smelting?

Smelting metals can indeed be a profitable venture if approached with caution and proper preparations. By obtaining the necessary permits and implementing safety measures, individuals can process various metals like copper, brass, and steel into ingots for sale to both retail and industrial customers. With the right equipment and careful planning, smelting offers an opportunity to generate income from the sale of these valuable metal products.

With proper precautions and permits, smelting metals like copper, brass, and steel can be a lucrative business. By transforming these metals into ingots and selling them to industrial and retail customers, individuals can generate income from this profitable venture. With careful planning and the right equipment, smelting offers a chance to profit from valuable metal products.

Which is more valuable, copper or brass?

When comparing the value of copper and brass, it is important to consider their prices, which can vary due to different alloys. Typically, copper is more expensive than brass and bronze. The decrease in bronze price could be attributed to its lower copper content. On the other hand, brass is the least expensive option as it contains a higher zinc content. Ultimately, the value of copper and brass depends on the specific application and market demand.

The value of copper and brass is determined by their prices, which can vary due to different alloys. Generally, copper is more costly than brass and bronze. The decrease in bronze price may be due to its lower copper content, while brass is the cheapest option because of its higher zinc content. Ultimately, the value of these metals depends on their application and market demand.

Exploring the Pros and Cons: Should You Consider Melting Copper into Bars?

Melting copper into bars is a popular practice among both hobbyists and professionals in the metalworking industry. One of the main benefits of this process is the ability to transform copper scrap into a more valuable and usable form. Copper bars are highly sought after for various applications, including electrical wiring, plumbing, and jewelry making. However, there are also downsides to consider. The process of melting copper requires specialized equipment and knowledge, which can be costly and time-consuming. Additionally, melting copper releases toxic fumes that can be harmful to human health and the environment.

Melting copper into bars can be a lucrative practice for metalworkers. Copper bars are in high demand for electrical wiring, plumbing, and jewelry making. However, this process requires expensive equipment and expertise. Furthermore, it poses risks to human health and the environment due to the release of toxic fumes.

From Scrap to Treasure: Evaluating the Value of Melting Copper into Bars

Melting copper scrap into bars can be a lucrative endeavor, but how do you determine the value of these bars? Evaluating the worth of melted copper involves several factors. First, the purity of the copper plays a significant role as higher purity levels fetch a higher price. Additionally, the weight of the bars and the current market price for copper are crucial elements to consider. Other factors such as the demand for copper, any impurities present, and the cost of refining also impact the overall value. By assessing these variables, one can determine the true worth of their melted copper bars.

How do you determine the value of melted copper bars? The value depends on factors such as purity level, weight, current market price, demand, impurities, and refining costs. Assessing these variables will help determine the true worth of the bars.

Unveiling the Benefits: Is Melting Copper into Bars a Lucrative Option?

Melting copper into bars can be a highly lucrative option for investors and businesses alike. Copper, a versatile metal with excellent electrical conductivity, is in high demand across various industries, including electronics, construction, and automotive. By transforming copper into bars, it becomes easier to store, transport, and trade. Moreover, melting copper into bars allows for easier measurement of purity and quality, increasing its value in the market. As the global demand for copper continues to rise, investing in this process can lead to significant financial gains for those involved in the copper industry.

Melting copper into bars offers lucrative opportunities for investors and businesses. Copper's versatility and high demand in industries like electronics, construction, and automotive make it an attractive investment. Transforming copper into bars enables easier storage, transportation, and trading, while also facilitating accurate measurement of purity and quality. With global copper demand on the rise, investing in this process can lead to significant financial gains in the industry.

The Art of Copper Metallurgy: Delving into the Worth of Melting Copper into Bars

Copper metallurgy is an ancient art that continues to captivate artisans and investors alike. The process of melting copper into bars not only enhances its aesthetic appeal but also increases its value. Copper bars, known for their lustrous shine and durability, have become a sought-after commodity in various industries. From jewelry-making to electrical applications, the versatility of copper bars is undeniable. Moreover, the increasing demand for copper in renewable energy technologies further solidifies the worth of this precious metal. As the art of copper metallurgy evolves, the value of melting copper into bars remains a testament to its enduring allure.

As copper metallurgy advances, the value of melting copper into bars continues to grow. The beauty and durability of copper bars make them highly coveted in industries such as jewelry-making and electrical applications. Additionally, the rising demand for copper in renewable energy technologies further solidifies its worth as a precious metal.

In conclusion, the decision of whether it is worth melting copper into bars ultimately depends on various factors. For individuals or businesses involved in the production or manufacturing industry, melting copper into bars may provide significant benefits in terms of cost-effectiveness, easier transportation, and better storage. Additionally, copper bars can serve as a valuable investment and a hedge against inflation. However, for those who do not have access to the necessary equipment or resources, the process may not be worth the time, effort, and expense involved. It is crucial to carefully consider the current market conditions, the intended purpose of the copper bars, and the potential return on investment before making a decision. Ultimately, conducting thorough research and seeking professional advice can help individuals make an informed choice regarding the value and feasibility of melting copper into bars.