Unveiling Engine Secrets: The Mystery Behind Unattached Cylinder Heads and Engine Blocks

18/09/2023

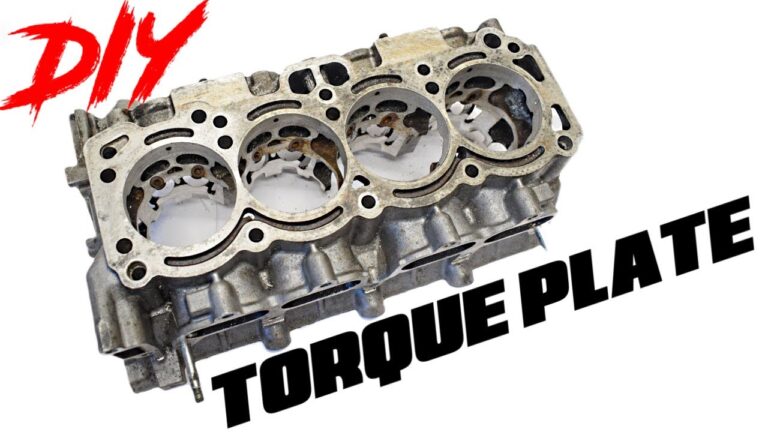

When it comes to the intricate inner workings of an engine, one might wonder why the cylinder heads and engine block are not attached. After all, these two components play crucial roles in the combustion process and overall performance of the engine. The answer lies in the need for flexibility and ease of maintenance. By keeping the cylinder heads and engine block separate, it allows for easier access to components such as pistons, valves, and camshafts, simplifying repairs and maintenance tasks. Additionally, this design choice allows for the efficient installation and removal of the cylinder heads, making it simpler to upgrade or modify the engine without having to replace the entire block. Understanding the reasons behind this design choice sheds light on the careful considerations made in engine design, ultimately contributing to the reliability and longevity of these powerful machines.

- What is the separation between the engine block and the cylinder head?

- Is the cylinder head attached to the cylinder block using bolts?

- What is the purpose of making cylinder heads removable?

- Understanding the Mechanics: The Surprising Reason Why Cylinder Heads and Engine Blocks Are Not Attached

- Unveiling the Engineering Mystery: Exploring the Purpose Behind the Separate Cylinder Heads and Engine Blocks

- Decoding the Design: The Ingenious Logic Behind the Unattached Cylinder Heads and Engine Blocks in Modern Engines

What is the separation between the engine block and the cylinder head?

The head gasket serves as a crucial barrier separating the engine block and cylinder head. Its primary role is to prevent the intermingling of coolant and oil within these components. By maintaining this separation, the head gasket safeguards the engine's overall functionality. Moreover, it plays a vital role in ensuring optimal compression within the cylinders. Therefore, the head gasket acts as a critical seal, preserving the integrity and efficiency of the engine block and cylinder head connection.

The head gasket's main function is to prevent coolant and oil from mixing in the engine block and cylinder head, which is crucial for the engine's performance and longevity. Additionally, it helps maintain optimal compression in the cylinders, ensuring the efficiency and integrity of the engine block and cylinder head connection.

Is the cylinder head attached to the cylinder block using bolts?

Yes, the cylinder head is typically attached to the cylinder block using bolts in conventional engine designs. In addition, the crankshaft main bearings are also bolted to the crankcase using separate bolts. This method of attachment ensures a secure and stable connection between these components, allowing the engine to function properly.

Conventional engine designs typically rely on bolts to attach the cylinder head to the cylinder block, as well as the crankshaft main bearings to the crankcase. This secure method of attachment ensures stability and proper functioning of the engine.

What is the purpose of making cylinder heads removable?

The purpose of making cylinder heads removable is to eliminate the cost and failure mode associated with head fasteners and head gaskets. By increasing cylinder pressure to improve engine efficiency, head gaskets are prone to failure. By making cylinder heads removable, these components can be easily replaced or repaired, reducing costs and minimizing the risk of a blown head gasket.

If cylinder heads are made removable, the cost and risk of head fastener and head gasket failure can be eliminated. This allows for easy replacement or repair of these components, reducing expenses and minimizing the chances of a blown head gasket when increasing cylinder pressure to improve engine efficiency.

Understanding the Mechanics: The Surprising Reason Why Cylinder Heads and Engine Blocks Are Not Attached

Understanding the mechanics behind the separation of cylinder heads and engine blocks is crucial for any automotive enthusiast. Contrary to popular belief, these two vital components are not directly attached to each other. The reason lies in the need for flexibility and temperature management. Engine blocks, being the foundation of the engine, are typically made of cast iron or aluminum, while cylinder heads, responsible for housing the combustion chambers, are made of aluminum for efficient heat dissipation. This design allows for expansion and contraction without causing damage, ensuring optimal performance and durability of the engine.

The separation of cylinder heads and engine blocks is not commonly understood. The need for flexibility and temperature management is behind this design choice. Engine blocks are made of cast iron or aluminum, while cylinder heads are made of aluminum for efficient heat dissipation. This allows for expansion and contraction without causing damage, ensuring optimal performance and durability.

Unveiling the Engineering Mystery: Exploring the Purpose Behind the Separate Cylinder Heads and Engine Blocks

In the world of automotive engineering, the separate cylinder heads and engine blocks have always intrigued enthusiasts and experts alike. These two components play a crucial role in the functioning of an engine, but the purpose behind their separation remains a mystery to many. While it may seem like an unnecessary complexity, the separation actually allows for greater efficiency and flexibility in engine design. This design choice enables easier maintenance, improved cooling, and the ability to optimize different aspects of the engine independently. By unveiling the engineering mystery behind separate cylinder heads and engine blocks, we gain a deeper understanding and appreciation for the intricacies of automotive design.

Why are cylinder heads and engine blocks separate? The separation allows for easier maintenance, improved cooling, and the ability to optimize different aspects of the engine independently, enhancing efficiency and flexibility in design. Understanding this engineering choice provides a deeper appreciation for the intricacies of automotive design.

Decoding the Design: The Ingenious Logic Behind the Unattached Cylinder Heads and Engine Blocks in Modern Engines

In the world of modern engines, unattached cylinder heads and engine blocks play a crucial role, but their design might seem puzzling to the untrained eye. However, there is an ingenious logic behind this engineering marvel. By separating the cylinder heads from the engine block, manufacturers can achieve several advantages, including improved cooling and easier maintenance. This design allows for better heat dissipation and enables mechanics to easily access the cylinder heads for repairs or modifications. Furthermore, the unattached nature of these components enables manufacturers to optimize the engine's weight distribution, resulting in better overall performance.

Separating cylinder heads from engine blocks offers more than just improved cooling and maintenance. This design also allows for efficient heat dissipation and easy access for repairs or modifications, while optimizing weight distribution for better performance.

In conclusion, the decision to not attach cylinder heads to the engine block may seem counterintuitive at first, but it is rooted in practicality and engineering considerations. By keeping these two components separate, manufacturers are able to improve the efficiency of the engine, reduce weight, and simplify maintenance and repairs. This design choice allows for easier access to the valves, pistons, and other critical components, making it more convenient for technicians to work on the engine. Additionally, it allows for greater flexibility in terms of customization and modifications. While it may seem unconventional, the separation of cylinder heads and engine blocks is a testament to the constant innovation and optimization in the automotive industry. As technology continues to advance, it is likely that even more unconventional designs and configurations will emerge, further pushing the boundaries of what we thought was possible in engine design.